Automation Technologies

Forbes Automation deals in many other customised solutions

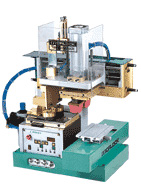

Pad Printing Machine (m/c code = FAT/PPM02)

Pad printing is an easy to operate, user friendly especially suited to printing on surfaces of any shape, with precise registration and high speed. Printing can be accomplished on surfaces of any textures or composition at a fraction of the time and cost required by other printing methods. Our state of the art standard open and sealed ink cup pad printing machines, have a wide range of image capabilities and multi-color configurations. The modular design of Rita Pad Printing Machines facilitates customization to your needs. Take a look at our gallery for some examples of our specialised industrial systems.

Technical Specification:

- Loading/unloading of component = manually

- Manpower required = 2 persons

- Teflon length cutting accuracy = +- 0.2mm

- Production rate = 1200~ 1400 Pcs/hour (Depends on the worker speed also).

- Table size = 800(l)* 800(w) * 700(h) MM.

- Pneumatic used = FESTO/SMC make

- PLC used = OMRON make Zen.

- Operating voltage = 220VAC

Other Information:

- Pay Mode Terms: L/C (Letter of Credit)

- Delivery Time: 10~12 weeks

Email: info@forbesautomation.co.in | Phone (24x7): +91 9873 171 057 / +91 9811 171 056

STANDARD MACHINES

These are time tested proven, reliable, cost effective machines with its successful use in various applications .The latest models are equipped with microprocessor based control panel with feather touch buttons & four digit electronic counter, with an additional facility of an accessory mode which you may incorporate at a later stage also, the round printing attachment, rotary table, conveyor etc.

These are time tested proven, reliable, cost effective machines with its successful use in various applications .The latest models are equipped with microprocessor based control panel with feather touch buttons & four digit electronic counter, with an additional facility of an accessory mode which you may incorporate at a later stage also, the round printing attachment, rotary table, conveyor etc.

The latest model FAT 100-GF has the advantage of the Closed Ink Cup System. The system ensures complete cut off of inks from undesirable atmospheric contact and leakages and also the ink can be maintained in the cup for several weeks.

FAT-S130

Pneumatic bench tampon printing machine with the well known "Hermetic System", developed by Tampoprint. Pneumatic drive.

Doctoring cup -130 mm

Cycles/hour - 800

Print image size (max) - 120 mm diameter

Cliché size - 150 x 300 mm

Applications:

- Printing on batteries

- Large bottle bodies, mugs

- Tube light chokes, small measuring scales

- CDs, T.V. cabinets

- Auto parts, dash boards, juicer mixer panels

- Washing machine panels

- Big enclosures, large plastic or metal trays requiring print area of about 120 mm

TECHNOLOGY | SEALED INK CUP - SERIES

| SEALED INK CUP | Sealed Ink Cup 130 | |

|---|---|---|

| Part no. | 01 00 81* | |

| Tampon cleaning as standard | No | |

| Single cycle | Yes | |

| Multiple printing | Optional | |

| Continuous run | Yes | |

| Place counter | No | |

| Variable speed control | Yes | |

| Ink cup/doctoring cup | Ø mm | 1200 |

| Variable doctoring contact pressure | No | |

| Cliché/Plate size | mm | 150 x 300 |

| Print image diameter | max. Ø mm | 125 |

| Tampon stroke onto workplace | mm | 25-120 |

| Tampon/ Pad stroke onto cliché | mm | 35-80 |

| Tampon/ Pad installation height | max. mm | 120 |

| Force of pressure | N | 1.800 |

| Drive | pneumatic | pneumatic |

| Control | pneum. sequential control | |

| Pneumatic supply | bar | 6 |

| Air consumption/Cycle | NL | 6 |

| Width | mm | 442* |

| Depth | mm | 1.100* |

| Height | mm | 850 |

| Weight | KG | 130 |

| * = with slide guard | ||

| FAT 60 | FAT 150 |

|---|---|

|

|

Our state of the art standard open and sealed ink cup pad printing machines, have a wide range of image capabilities and multi-color configurations. The modular design of Rita Pad Printing Machines facilitates customization to your needs. Take a look at our gallery for some examples of our specialised industrial systems.

Closed Cup

| MODEL | PRINT AREA Ø | PRINTING SPEED PER HOUR | AIR CONSUMPTION | CURRENT CONSUMPTION | DIMENSION (W x H x D) | WEIGHT |

|---|---|---|---|---|---|---|

| FAT-60GF | 55mm | 1800 | 0.33 m 3/hr | 15W | 450 x 610 x 270mm | 50 kg |

| FAT-100 GF | 85mm | 1600 | 0.60 m 3/hr | 15W | 530 x 680 x 300mm | 70 kg |

| FAT-150 D- GF | 55 mm | 1000 | 1.04 m 3 /hr | 15W | 640 x 750 x 340mm | 90 kg |

Open Inkwell

| MODEL | PRINT AREA Ø | PRINTING SPEED PER HOUR | AIR CONSUMPTION | CURRENT CONSUMPTION | DIMENSION (W x H x D) | WEIGHT |

|---|---|---|---|---|---|---|

| FAT-100 | 85mm | 1600 | 0.60 m 3 /hr | 15W | 530 x 680 x 300mm | 70 kg |

| FAT-150 | 125mm | 1000 | 1.0 m 3/hr | 15W | 640 x 750 x 340mm | 90 kg |

| FAT 150 / 180° | 1000 strokes/ hr | 5.2 m 3 / hr. | 15W | 640 x 750 x 340 mm | 90 kg. | |

| FAT-100/180° | 1600 strokes/ hr | 2.5 m 3 / hr. | 15W | 485 x 710 x 250 mm | 70 kg. |